Cooling Towers: HVAC Series Part III

This Cooling Tower blog is the third in a series of blogs that will explore how Veris Industries products can be used to monitor and regulate heating, ventilation, and air conditioning (HVAC) applications.

In a commercial chiller, water is used to extract heat from the refrigerant on the condenser side of the chiller before the refrigerant is recirculated to cool water on the air handler side of the chiller. If the heat extracted from the refrigerant cannot be used in other building processes, it remains in the water. This heated water is pumped to a cooling tower.

How Cooling Towers Work

A cooling tower is a heat rejection device that extracts waste heat to the atmosphere by cooling a stream of hot water in the tower. This type of heat rejection is termed "evaporative" because it allows a small portion of the water being cooled to evaporate into a moving air stream. This heat removal then provides significant cooling to the rest of the water stream. The heat that is transferred from the water stream to the air stream raises the air's temperature and its relative humidity to 100%, and this air is discharged to the atmosphere. The remaining cooled water is pumped back to the condenser side of the chiller. Additional water is added to the cooled water stream to compensate for volume losses due to evaporation. Because the cooling tower utilizes an evaporative process, it must be placed outside of the building. Cooling towers can be found on the roofs of large buildings or on a cement pad or risers.

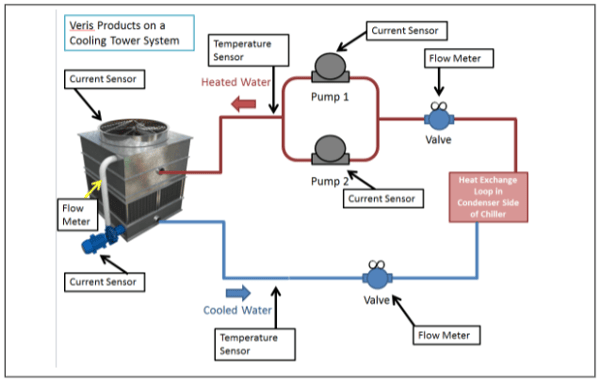

Cooling Tower Diagram

How Cooling Tower Systems Work with Veris Products

| Product Family | Why it is used on a Cooling Tower |

| Flow Meters | Monitors flow of the supply and return heating loop. The water utility will charge the end user based on the amount of water supplied. The end user is also charged for the amount of water dispelled into the sewer system. In some climates, evaporation can be as much as 50% = 60%. Utilizing a flow meter on both the supply and the sewer drain will save the end user money by capturing the actual amount of water sent down the drain. The difference between the amount of water supplied and the amount of water sent down the drain is the volume of water lost due to evaporation. With this data from the supply and the drain flow meters in hand, the end user will receive a credit for the evaporation losses. |

| Temperature | Immersion temp in the cooling tower is a control input for fat rotation. The cooling tower fan removes a large amount of the heat to prepare the water for conditioning (via coolant) in the chiller. |

| Current Sensors | Monitors run status of pumps and fans to ensure that they are working when needed. Proof of functionality. No need to manually check each fan or pump. (If current is flowing, the fan or pump is working.) |