Guide to Air Handling Units (AHU)

This air handling unit blog post is the first in a series that will explore how Veris Industries products can be used to monitor and regulate heating, ventilation, and air conditioning (HVAC) applications.

What is an Air Handling Unit?

An air handler, or air handling unit (often abbreviated to AHU), is a device used to condition and circulate air as part of a commercial or industrial HVAC system. Usually, an air handler is a large metal box containing a blower, heating and/or cooling elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to duct work that distributes the conditioned air through the building, and returns it to the AHU. Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served, without ductwork.

Air Handling Unit Basics

The number and types of AHUs used vary based on the size of the building and how the building is used. For example, in a hospital or lab environment multiple AHUs may be needed to isolate rooms and prevent cross contamination. Air handlers also dehumidify or humidify air; regulate the mix of outside and recirculated air; and help control pressurization inside a building.

Air Handling Unit Diagram

.png?width=526&name=Inside%20an%20Air%20Handler%20Unit%20(AHU).png)

The Purpose of Air Handling Units

As mentioned previously, an air handling unit helps circulate air. Air handling units are widely used in large facilities- such as malls and schools. Due to the strict regulations concerning carbon dioxide and air cleanliness, AHU's are perfect since they have the capacity to circulate air in large spaces.

What makes air handling units so appealing is that they deliver outside air into rooms, providing more quality air and reducing safety concerns.

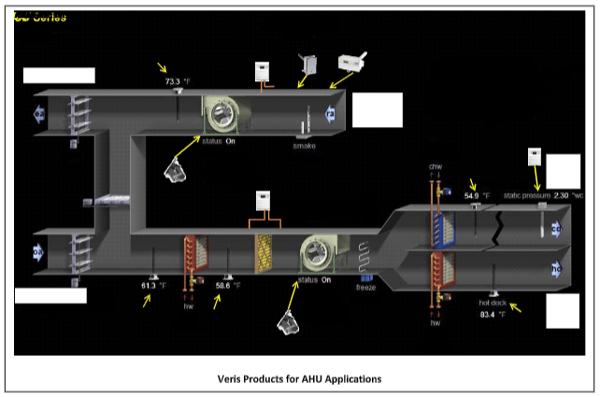

How Air Handling Units Work with Veris Products:

| Product Family | Why it is used on an AHU |

| Pressure | Monitors supply and return duct pressure. Can be used to monitor filter status. Provides a control point for fan speed and air flow through duct work. Can also be used to provide building zone pressure (negative or positive) to either prevent or allow the inflow of outside air. |

| Humidity | Used to monitor duct, space and outdoor RH – mostly for building comfort. Provides input to determine how much outside air should be introduced into the building. Some manufacturing and lab processes require controlled humidity. |

| Temperature | Monitors return and supply duct temperature. Control point for air recirculation versus introduction of outside air. Provides input for environment comfort – fan control. |

| Current Sensors | Monitors run status of fan motors – fan status, on / off, belt loss, etc. Provides proof of airflow – if the fan is running, air is moving. |

| Carbon Dioxide (CO2) | Monitors carbon dioxide for Demand Control Ventilation (DCV). Monitoring CO2 levels for demand control allows the end user to only bring in fresh air when needed. It costs money and requires more energy to condition outside air versus recirculating the existing conditioned air in a building. |

Veris Industries has a complete line of environmental and current sensing products for your AHU applications. Visit our website or call our sales team for more details.